Differences and How to Choose the Right Abrasives

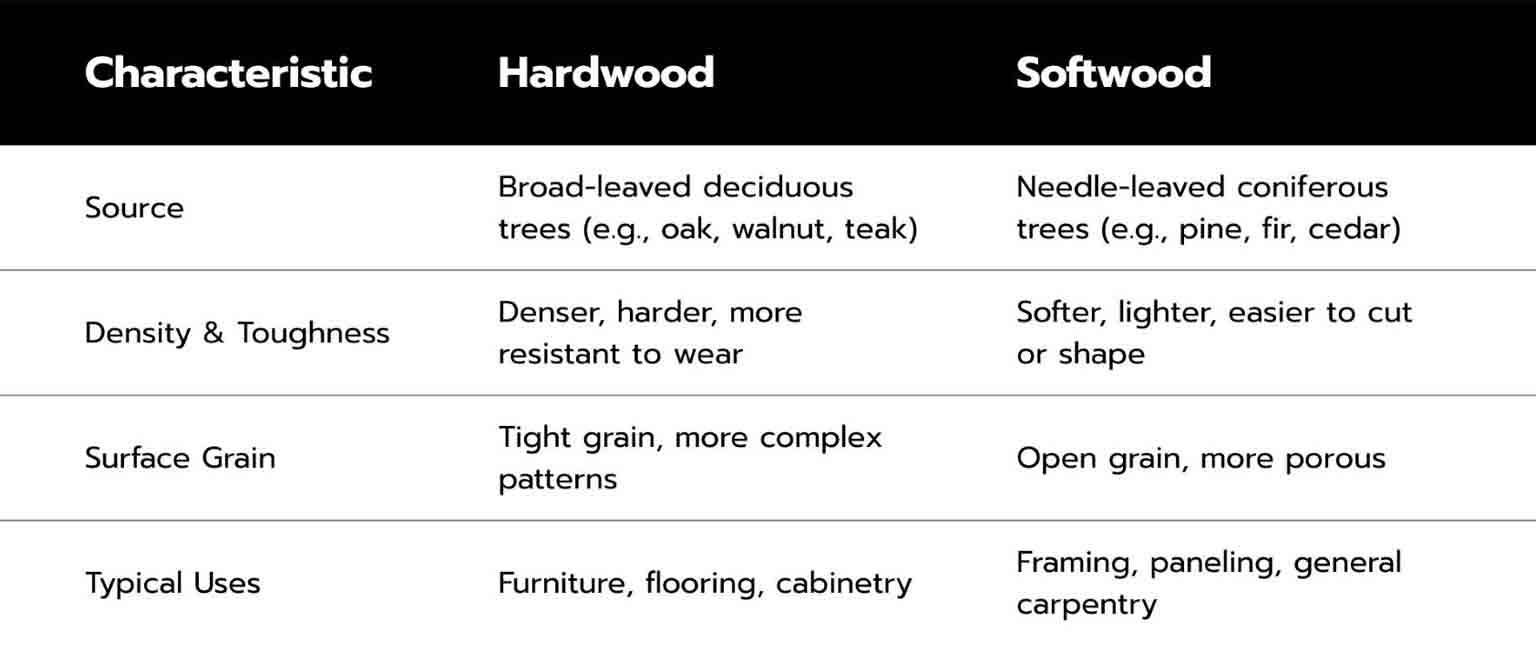

When working with wood, recognizing the basic differences between hardwood and softwood is key—not only for selecting the right material but also for choosing the appropriate abrasives during surface preparation. The correct abrasive can dramatically affect the finish quality, work time, and lifespan of your tools and materials.

Key Differences Between Hardwood and Softwood

How to Choose Abrasives for Wood Types?

Choosing the right abrasive involves considering the grit size, abrasive material, and tool compatibility (e.g., hand sanding, orbital sander, belt sander). The goal is to remove imperfections efficiently without damaging the wood, especially during surface preparation for finishing.

Abrasives for Hardwood

Hardwoods require tougher, more durable abrasives due to their high density.

-

- Recommended Grits:

- Start with 80–100 grit for initial sanding or shaping.

- Move to 120–150 grit for smoothing.

- Finish with 180–220 grit before applying finishes.

- Best Abrasive Materials:

- Aluminum Oxide – Durable and long-lasting; ideal for hardwoods.

- Zirconia Alumina – More aggressive; good for heavy material removal or large surfaces.

- Ceramic Abrasives – Extremely tough; ideal for industrial or high-volume use.

- Recommended Grits:

Abrasives for Softwood

Softwoods are easier to sand but more prone to gouging and uneven finish if the wrong abrasive is used.

-

- Recommended Grits:

- Begin with 100–120 grit to prevent surface damage.

- Progress to 150–180 grit for intermediate smoothing.

- Finish with 220 grit or higher if preparing for staining.

- Best Abrasive Materials:

- Aluminum Oxide – A multi-purpose abrasive that’s gentle enough for softwood.

- Silicon Carbide – Sharp but brittle; useful for finer sanding stages.

- Garnet – Natural abrasive that wears quickly; good for hand sanding and light jobs.

- Recommended Grits:

Selecting the right abrasive for hardwood or softwood isn’t just about grit—it’s about using the right material and method for the wood’s characteristics. Hardwoods demand tougher, more resilient abrasives, while softwoods benefit from a gentler touch to preserve surface quality. By choosing wisely, you’ll save time, reduce waste, and achieve superior results in every woodworking project.